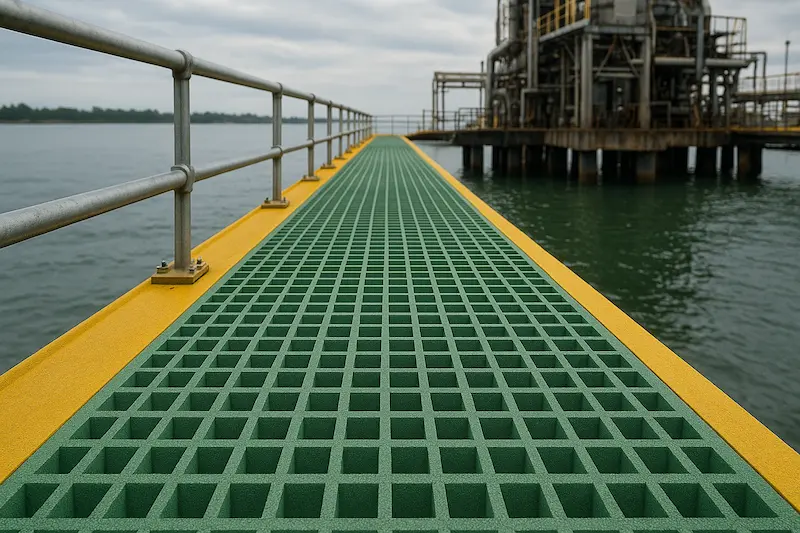

As industries continue to replace metal with lighter, corrosion-resistant materials, FRP (Fiberglass Reinforced Plastic) gratings have become a vital component in infrastructure, marine, and chemical applications.

These gratings offer outstanding strength-to-weight ratios, excellent chemical resistance, and long-term durability — making them a preferred solution for modern engineering projects.

This article reviews the top five FRP grating manufacturers in 2025, highlighting their main strengths and limitations from a professional and practical standpoint.

1. Fibergrate Composite Structures (USA)

Strengths

Fibergrate is one of the most experienced FRP grating manufacturers globally, pioneering molded and pultruded fiberglass grating technology. Its products are well-known for consistent resin distribution, non-slip surfaces, and superior corrosion resistance.

With certifications under ASTM, ISO, and OSHA standards, Fibergrate maintains high quality and global trust. Their modular systems like Dynarail® and Dynaform® combine gratings, handrails, and profiles for complete structural solutions.

Limitations

However, Fibergrate’s pricing is relatively high, and international lead times can be longer due to centralized U.S. production. For budget-conscious projects, cost can be a barrier compared to Asian suppliers.

2. Strongwell Corporation (USA)

Strengths

Strongwell is known for its engineering precision and pultrusion expertise. The DURAGRID® and DURADEK® series are designed for high load capacity, UV resistance, and chemical stability.

Strongwell’s R&D capability and in-house testing laboratories ensure compliance with ASTM and ISO standards. Its gratings are trusted for refineries, bridges, wastewater plants, and marine decks.

Limitations

The company primarily targets high-end projects, and its product range in molded gratings is narrower. Additionally, Strongwell’s focus on the U.S. market may limit accessibility for overseas contractors.

3. Machs Composite Material Co., Ltd. (China)

Strengths

Machs, based in Nantong, China, is a fast-growing global supplier specializing in FRP molded gratings, pultruded gratings, stair treads, and handrail systems.

Its advantages include factory-direct pricing, strong customization, and strict quality control. Products are made in modern automated facilities and conform to ASTM, ISO, and CE standards.

Machs’ gratings are available in multiple resin systems — orthophthalic, vinyl ester, and phenolic — offering strong corrosion resistance across marine and chemical environments. The company exports to 30+ countries, serving ports, desalination plants, and industrial platforms.

Limitations

Machs’ brand recognition in Western markets is still developing compared to long-established U.S. companies, but its cost-effectiveness and reliability continue to expand its global footprint.

4. Bedford Reinforced Plastics (USA)

Strengths

Bedford’s ReadySeries® gratings are modular, lightweight, and easy to assemble. The company provides custom FRP profiles and structural platforms, offering aesthetic designs for architectural and industrial projects alike.

Its UV-resistant materials and non-conductive properties make Bedford’s products ideal for outdoor and electrical applications.

Limitations

Customization depth is moderate compared to suppliers like Machs, and logistics costs make Bedford less competitive for projects outside North America.

5. AIMS Composites (USA)

Strengths

AIMS Composites offers both molded and pultruded FRP gratings, featuring fire-retardant resin systems and OSHA-compliant surface designs. Their DeltaGrid and DeltaRail series are popular for safety platforms, stairs, and handrails.

AIMS is also praised for its responsive support and flexibility for smaller-scale custom projects.

Limitations

However, AIMS’ global presence is limited. Most production and distribution are focused in the U.S., which restricts access for international procurement and large-scale orders.

Final Thoughts

Each of these manufacturers brings unique advantages to the global FRP market.

- Fibergrate and Strongwell lead in innovation and structural engineering reliability.

- Machs (China) delivers cost-efficient, high-quality FRP gratings with global supply capability.

- Bedford and AIMS excel in modularity and small-scale engineering flexibility.

Selecting the right FRP grating manufacturer depends on project environment, budget, and performance priorities.

Article reference source: Machs – 2025 Top 10 FRP Grating Manufacturers

Comentarios